What are glass fibers?

Glass fibers in English: Glass fiber is the most popular reinforcer used in the composite industry and there are different types of it commercially. The chemical composition of these fibers is different and each is suitable for a specific application.. Unlike other polymeric materials that have a chain structure, glass has a network structure. Despite this, glass resistance is very high.” Twice the strength and durability of other non-metallic fibers. Molten glass is made into string-shaped cotton threads. Glass fibers are delicate and flexible fibers that are made of glass.. Roving (glass fiber) Very thin filaments are made of glass with a constant diameter and unlimited length. Glass fibers are produced with a diameter of 5 to 25 microns. Structurally, the difference between fiberglass and fiberglass (glass wool) This is due to the fact that the diameter of the fibers in non-uniform glass wool and its length is limited. Also, in the process of producing glass wool, due to the difference in the type of cooling, the glass structure is brittle and differentiates glass wool so that glass fibers are used to increase tensile strength and strengthen composites, but glass wool is used as thermal insulation. They use. Of course, the use of glass sheets as thermal insulation is also common. Glass fibers are used in many plastic products as reinforcing agents. Composite materials as (Glass- Reinforced Plastics(GRPs are known to be one of the most popular uses for glass fibers.

The glass fibers we know today were mass-produced in 1938 by Onzkornning.. The properties of glass fibers such as tensile strength, Young's modulus and chemical durability are measured directly from the fibers.. Properties such as density and refractive index are measured in both cases. Application for electrical use of aircraft fuselage Preparation of fire-retardant molding paste Chemical compounds of glass fibers The difference between chemical compounds in different types of glass is due to the difference in the raw materials.. These chemical fluctuations significantly change the chemical and physical properties of different types of glass. Applications are about 90% of the fibers used in glass fiber engineering composites. Glass fiber has good strength and hardness, maintains its mechanical properties at high temperatures, has good moisture and corrosion resistance and is relatively inexpensive.. The division of the six types of glass fibers and the combination of its percentages are shown below: glass- E General glass consumption- R higher mechanical properties glass-S higher mechanical properties glass-c chemical resistance suitable glass-ECR acid resistance and good open glass-AR good acid and base resistance good

Applications of glass fibers in industry

Glass fibers have a wide range of applications in various industries such as chemical, military, aerospace, shipbuilding, automotive and electronics due to their special physical and chemical properties or lack of moisture absorption and insulation against heat, electricity and sound.. The most common use of fiberglass is in the manufacture of GRP pipes and fiberglass parts (Composites based on a variety of resins with fiberglass reinforcement), Marine vessels and thermal-moisture insulation. These products are made by mixing glass fibers with various resins with the help of chemical catalysts at room temperature or under certain temperature conditions and pressures, which are also called reinforced plastics.. The resins used in these products include thermostat, polyester, epoxy, phenolic, vinyl ester and 2 resins. ..

From an industrial point of view, glass fibers are usually considered as plastic reinforcers and along with these plastic materials, they are used as various composites and in the form of various products in various industries..

Fiberglass and composite consumables

Glass fiber is the most popular reinforcement used in the composite industry, and there are several types of it commercially available, some of which are::

E، S،C،ECR،AR. The chemical composition of these fibers varies and each is suitable for a specific application.

About 90% of the fibers used in engineering composites are glass fibers. Glass fiber has good strength and hardness, maintains its mechanical properties at high temperatures, has good moisture and corrosion resistance and is relatively inexpensive. .

Glass fibers are used in the following cases due to their excellent elasticity, low density, resistance to thermal shocks, low price and electrical insulation.:

Insulation, electrical and audio industries, sports, aerospace, automotive, wind power, shipbuilding, military, construction and chemical industries can be named..

Depending on the application of these fibers, different types can be used:

Type E fibers for electrical applications and mechanical reinforcement

Type S fibers for applications with high mechanical properties High strength reinforcing

Type C fibers for chemical applications and corrosion resistance

Type R fibers for applications with high mechanical properties

ECR good acid and base resistance

AR-glass very good acid and base resistance

Different shapes of glass fibers

Category (strand): A bunch of a few tau (tow) Is formed and each tau indicates the number of leaflets (fiber) Which are spun from a bush, for example, can be two hundred fibers. A set of categories, a string (roving) is named. A short twist is given to the string to make it easier to work with. For continuous fiber composites, the choice of fiber type depends on the process of forming and the amount of fiber arrangement..

The strings can be broken (chopped) And to produce glass felt (strand mat chopped) used. In this case of a binder (binder) They are used together to make the fibers look fixed. The above binder is soaked when the fibers are impregnated with resin (wet-out) Controls and therefore the random arrangement of fibers in the felt is maintained. Binder selection is based on the application of materials and the durability of a composite part can be affected by the type of binder..

Continuous fiber felt ( continuous random mat ) Another form of fiber used is that in which continuous fibers are formed by the random arrangement of felt.. This form of fiber is suitable for sharp and angular parts of the mold and in this case the fibers do not break..

The role of glass fibers in concrete

The advantages and important role of fibers in fiber concrete have been of interest to most engineers and designers. Proper design and workmanship, very high resistance and resistant to compressive and tensile forces and the ability to absorb energy and resistance to cracking are the prominent features of this type of concrete..

The advantages of these products are: :

- Reduce the thickness of the concrete slab while maintaining its strength.

- Reinforcement of concrete slab in the corners and right angles of concrete slab.

- Control of hair cracks in the range of concrete shrinkage.

- Improving the physical, chemical and mechanical properties of concrete- Reduction of shrinkage cracks in the initial concreting time.

- Prevent concrete from cracking due to impact and dynamic loads.

- Increasing the compressive strength of concrete up to 1000 kg / cm in single-axis testing.

Where is fiber concrete used?

Fiber reinforced concrete has various applications. Types of concrete fibers in the construction of concrete bridges, airports, military structures, road construction and paving of sidewalks, construction of concrete dams, tunnels, power plants, refineries, water tanks, retaining walls, Foundation, Construction of industrial sheds and industrial flooring, storage of pharmaceutical and food materials, flooring of multi-storey car parks, construction of prefabricated building parts, etc..

What are the benefits of fiber concrete?

The flexibility of fiber concrete, as well as the properties of plastic materials, has made it impossible for fiber concrete to break suddenly.. Because the fibers in the concrete body are scattered in all directions, if a crack is formed in different directions, the fibers will form bonds and prevent the crack from spreading.. Therefore, fiber fibers are actively involved in limiting the crack width and increase the exploitation capacity of concrete by forming small micro-cracks..

Fiber-reinforced concrete has superior mechanical properties such as compressive strength of more than 150 MPa, high elastic modulus, high elastic limit, tensile stress, multiple fracture energy of traditional concrete values and high capacity after cracking..

The following are some of the other benefits of fiber concrete:

- Increase in energy absorption

- High abrasion resistance

- High relative deformation capacity

- Excellent impact resistance

- How do fibers work in concrete?

- FibersAggregate And prevent coarse aggregates from separating due to vibration and gravity, ensuring better cohesion.. As a result, a uniform mixture of concrete and fibers is produced, which slowly transfers water to the surface during traction, resulting in less cracks in the concrete..

- What is the method of using fibers in concrete and how much is used?

- Fiber can be added to the mixer at any time. The fibers can also be added to the mixing water at the end and poured into the mixer, in which case stirring should be continued for another 3 to 4 minutes to achieve a uniform mixture.. If you want to use ready-mixed concrete, you can gradually pour the fibers into the mixer truck, and stirring at high speed should continue until you are sure that the fibers are fully distributed inside the concrete.. The amount of fiber consumption will vary from 0.6 to 3 kg per cubic meter, depending on the desired performance..

- Improving the mechanical properties of concrete using fiber concrete

- Using 4% fiber, the flexural strength of concrete increases by 2.5 times. Concrete containing fiber materials has a failure resistance of about 10 to 40 times the stress compared to plain concrete.. The impact strength of fiber concrete is generally 5 to 10 times higher than that of plain concrete, which varies depending on the amount of fiber used in different concretes..

- Is there any economic justification for using fiber concrete?

- The use of fiber concrete in all cases from traditional concrete is not affordable. But according to estimates made by some experts in the country, in places where high execution speed is considered or the need for concrete spraying(Shotcrete) On surfaces where traditional mesh is difficult or time consuming or unresponsive, the cost of using fiber concrete is lower than traditional concrete..

- But if we avoid resorting to new technology because of the risk involved in investing, we will see that traditional technology, in the absence of new technology, will waste a very large amount of our capital.. For example, fine-grained products produced by non-standard old methods increase the percentage of cement used in the building, leading to cracks and debris in the concrete..

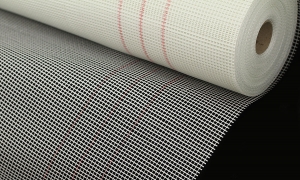

فایبر مش ها ( مش های فایبرگلاس)

فایبرمش ها (مش های فایبر گلاس) برحسب وزن و سایز شبکه ها دارای تنوع بسیاری هستند. این توری ها از الیاف شیشه به عنوان تقویت کننده و از مواد پلیمر به عنوان زمینه استفاده می شود. که این تنوع امکان استفاده از این محصول را در مکان های مختلف امکان پذیر می سازد.

ویژگیهای الیاف شیشه به کار گرفته شده در تولید :Glass Mesh

مقامت شیمیایی: الیاف شیشه در برابر بسیاری از مواد شیمیایی مانند اسیدها مقاوم بوده و از بین نمیرود، همچنین قارچها باکتریها و جانوران موزی نمی توانند بر آن تاثیر بگذارند.

مقاومت در برابر رطوبت: الیاف شیشه رطوبت را جذب نمی کند، بنابراین متورم نمی شود و کش نمیآید این الیاف در محیط های مرطوب نیروی مکانیکی خود را حفظ می کنند .

خواص الکتریکی: الیاف شیشه عایق الکتریستیه هستند .

الیاف شیشه استحکام کششی بالای دارند و الاستیسیته کاملی نیز دارند یعنی ازدیاد طول آنها متناسب با نیروی اعمال شده می باشد و با برداشتن نیرو به حالت اولیه خود باز می گردند .

الیاف شیشه مقاومت حرارتی خوبی دارد به دلیل طبیعت غیر عالی خود قابل احتراق نبوده و انبساط حرارتی پایین و هدایت حرارتی بالای دارند.

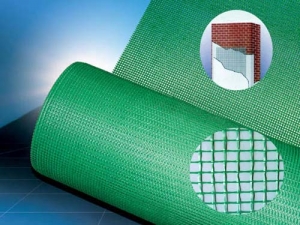

کاربردهای توری الیاف شیشه ای :

تسلیح سطح دیوار: فایبر مش ها جهت تسلیح گچ و سیمان جهت آماده سازی سطح دیوار (نازک کاری) کاربرد داشته و به دلیل انعطاف پذیری بالا و مقاومت کششی مطلوب جایگزین مناسبی برای محصولات مشابه فلزی (رابیتس، توری مرغی) می باشد. تسلیح عایق های رطوبتی: فایبرمش ها بهترین گزینه جهت استفاده به همراه عایق های رطوبتی در

پشت بام ،استخرها، کف و دیوارهای سرویس های بهداشتی و غیره می باشد.این محصول با انعطاف پذیری و مقاومت کششی بالا و چسبندگی مطلوب مجموعه مناسبی را برای عایق بندی ایجاد می نماید. تقویت سنگهای ساختمانی: یکی از کاربردهای فایبرمش ها تقویت سنگ های ساختمانی می باشد. پس از برش قله های سنگ در کارخانه های سنگ بری و تبدیل شدن آنها به ورق مسطح یک لایه از این مش ها با رزین مخصوص به پشت سنگ نصب می شود.این مش کمک می کند تا به هنگام پولیش و حمل و نصب در صورتیکه سنگ دچار ترک شد از هم جدا نشده و به همان صورت کار گذاشته شود.

عایق های سرد: از فایبر مش ها در عایق کاری سرد لوله ها و تاسیسات در ساختمانها ، کارخانه ها و پالایشگاهها نیز استفاده می گردد.

از دیگر کاربردهای مش های فایبرگلاس

تقویت نما های سنگ مرمر .

تعمیر سطحی بتن و شکافها .

مقاوم سازی مصالح ساختمانی .

تقویت و تثبیت مواد ، عایق و قیر .

تقویت بافت طبیعی سنگ در سنگبری .

جهت تقویت اتصالات و محل تلاقی دیوارها .

ضد زلزله نمودن سازه ها با مصالح قیر یکپارچه.

زیر سازی برای نصب سنگ، کاشی و سرامیک .

جهت استفاده در زیر سقف سوله ها به جای توری فلزی .

بالابردن مقاومت کششی و استحکام مصالح ساختمانی .

ایجاد بافت یک پارچه در دیوارها و کف جهت جلوگیری از ترک .

تقویت سقف و دیوارهای گچی و سیمانی و بتونی پیش ساخته .

قابل استفاده بر روی کلیه سطوح قبل از عملیات بتن کاری و گچ کاری .

جهت تعمیر ترکها و سایر ضایعات در انواع سطوح و پیشگیری بوجودآمد مجدد آنها ..